The Meat Thermometer Problem: Why 70% of Breweries Are Non-Compliant (And What Happens Next)

Most breweries and beverage co-packers rely on meat thermometers and spot checks to document pasteurization—but FSMA requires validated, continuous monitoring of time and temperature. Here’s why nearly 70% may be non-compliant and what that means for your operation.

Your Pasteurizer Is Costing You More Than $842,000 a Year (And You Don’t Even Know It)

Most tunnel pasteurizers appear stable, compliant, and reliable. But in many breweries, they quietly limit growth. Conservative operation without continuous cold-spot data often leaves 3–5% of throughput unused—showing up not as downtime, but as constrained volume and unrealized revenue year after year.

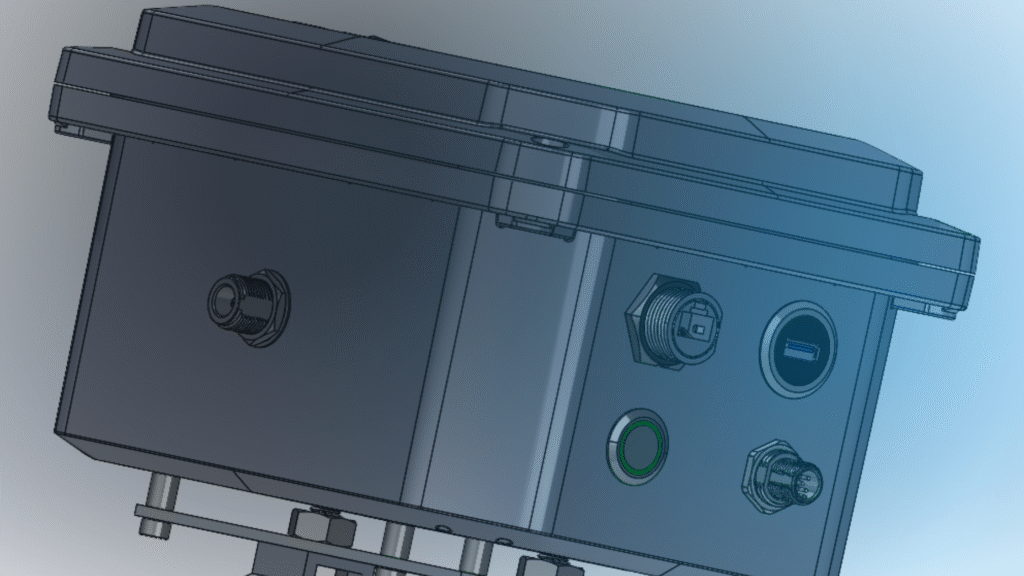

From Sentry to SCOUT + COMMANDER: Why the Transition Matters

The Sentry era is coming to a close. With replacement parts becoming obsolete and compliance expectations rising, standing still is no longer a safe option. This article explains why Extant Dynamix is transitioning customers to SCOUT + COMMANDER and how this next-generation platform delivers the reliability, precision, and audit-ready confidence modern breweries and co-packers need.

Always Connected: How the LIEUTENANT Bridges Every Gap in Brewery Monitoring

A single Wi-Fi dropout can turn a smooth pasteurization run into a data nightmare.

That’s why Extant Dynamix built LIEUTENANT, the always-on bridge that keeps your data flowing and your records intact, even when the internet doesn’t.

Optimizing Pasteurization Time Without Sacrificing Safety or Quality

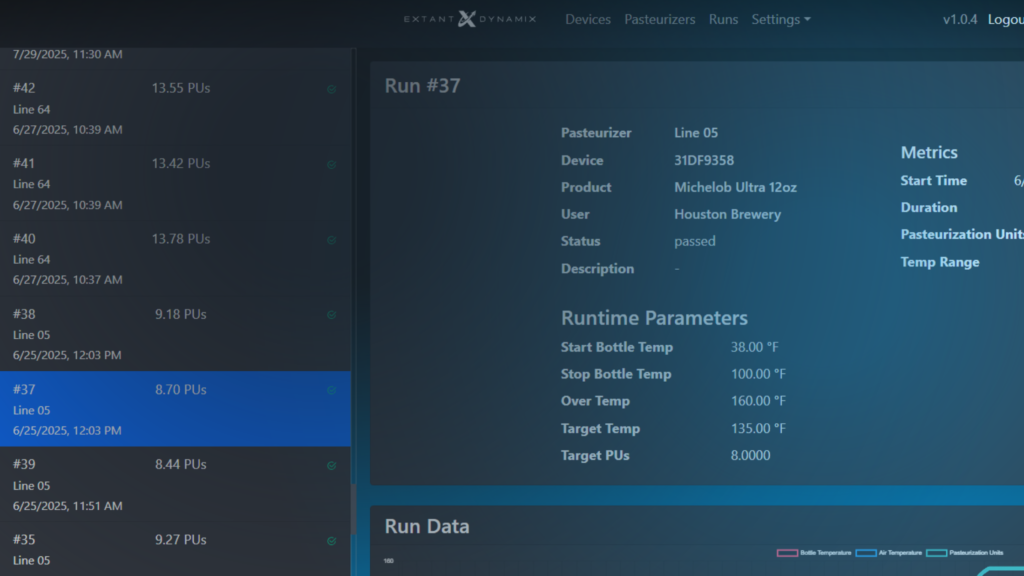

Optimizing pasteurization isn’t about running longer—it’s about running smarter. This piece shows how data-driven control and real-time visibility with SCOUT + COMMANDER help breweries shorten cycles, maintain safety, and boost throughput without compromising quality.

Pasteurization Monitoring & Compliance: Navigating Regulatory Requirements With Ease

Evolving FDA and global standards make compliance a constant challenge. Manual logs leave gaps; automated, real-time pasteurization monitoring closes them. With Extant Dynamix’s SCOUT + COMMANDER, breweries move from audit stress to audit confidence. The result: precise PU delivery and records regulators trust.

Understanding PU (Pasteurization Units): What They Mean and Why They Matter

Shelf life comes down to one number: the Pasteurization Unit (PU). Miss it and you risk waste, flavor loss, and compliance issues. With SCOUT + COMMANDER, Extant Dynamix delivers real-time accuracy and audit-ready data that keep every batch safe, consistent, and compliant.

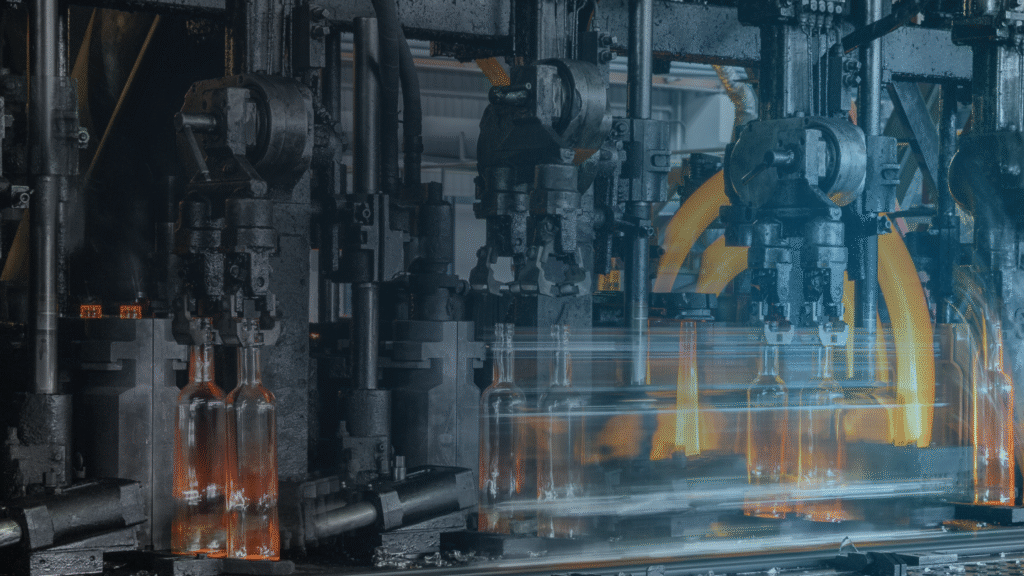

Transitioning From Manual to Automated Pasteurization Monitoring

In an industry defined by both tradition and innovation, breweries face a critical question: how much longer can manual pasteurization monitoring hold its ground? For technicians, process engineers, and QA managers, the truth is unavoidable. Manual methods—clipboards, irregular water-bath checks, handwritten logs—are riddled with inefficiencies and prone to error. In an era where margins are […]

Reducing Operational Costs Through Advanced Pasteurization Monitoring

Hidden inefficiencies in pasteurization raise costs and strain operations. SCOUT + COMMANDER turns it into a precision-driven advantage with real-time PU tracking, AI self-calibrating probes, rugged wireless hardware, and cloud dashboards—enabling faster anomaly detection, reduced batch loss, and up to 20% lower energy costs. Built for seamless integration and growth, it transforms pasteurization from a static expense into a strategic lever.

Maximizing Brewery Efficiency With Precision Pasteurization Monitoring

In today’s high-stakes brewing environment, pasteurization consistency is no longer a luxury, it’s a necessity. This blog explores how outdated systems create hidden inefficiencies and how SCOUT + COMMANDER by Extant Dynamix delivers real-time, precision-driven monitoring designed specifically for modern breweries. Discover how intelligent automation can help you reduce waste, protect margins, and future-proof your operations.